Thermodynamics and thermal conductivity

The training laboratory is designed for institutions of higher, secondary specialized and vocational education

The laboratory consists of the following equipment:

|

NTC-14.57 “Thermodynamics. Inverse thermodynamic cycles (devices)” The training laboratory equipment is designed for studying the heat transfer processes, as well as to study the operation and general characteristics of a split system in various modes. More details >> |

|

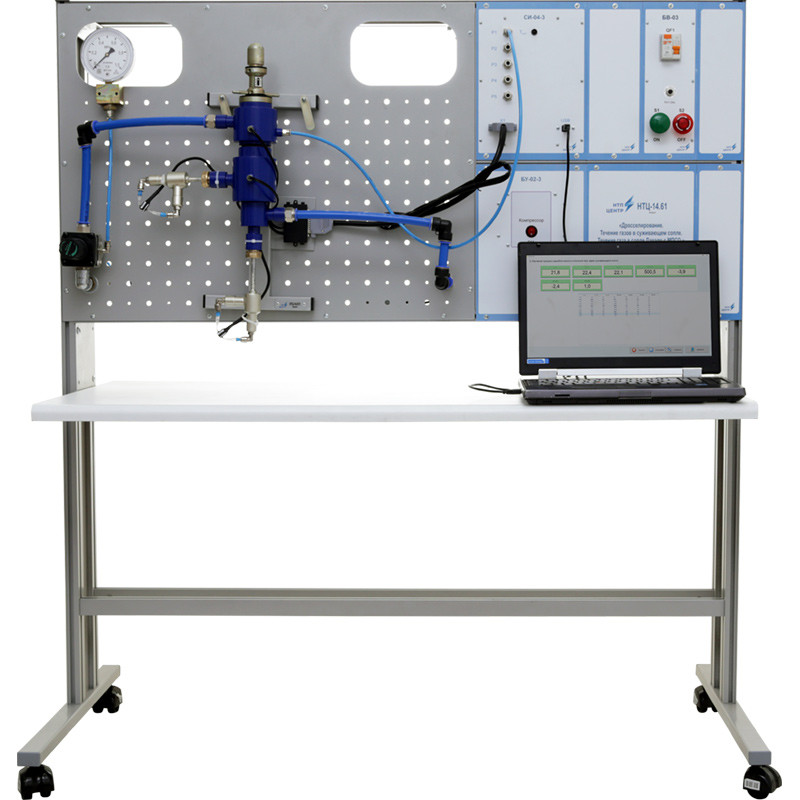

NTC-14.61.B “Throttling. Gas flow in narrowing nozzle. Gas flow in Laval nozzle with MPMS” The training laboratory system is designed for practical study of methods and measurements used in studying thermodynamic and heat transfer processes in gas streams. More details >>

|

|

NTC-14.79.B “Thermodynamic processes with microprocessor measurement system (MPMS)” The laboratory stand is designed for studying thermodynamic processes. More details >>

|

|

NTC-18.54 “The study of heat processes” The training laboratory system is designed as a educational equipment to carry out laboratory experiments to study “Heat processes and heat transfer”. More details >> |

|

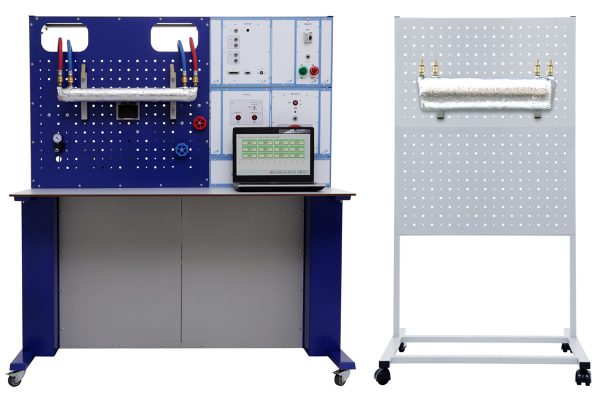

NTC-18.74.B “Investigation of heat transfer with MPMS” The training laboratory equipment provide opportunity to acquire the skills of experimental determining the thermal conductivity coefficients of various materials, heat transfer coefficients, emissivity factor and degree of blackness. More details >> |

|

NTC-22.05.1.B “Heat engineering and thermodynamics” The universal laboratory bench is performed as a basis with integrated measurement system, control module and work surface for installation of investigated blocks. More details >> |

|

NTC-22.05.2.B “Fluid thermal engineering” The laboratory equipment allows to investigate heat exchange processes with fluid flowing in a pipe or in a heat exchanger. More details >> |

Русский

Русский