NTC-22.05.1.B “Heat engineering and thermodynamics”

Br0.00

The universal laboratory bench is performed as a basis with integrated measurement system, control module and work surface for installation of investigated blocks.

- Description

- Experiments provided

- Technical specifications

- Video

- Scope of delivery

- Additional equipment (specified when ordering)

Constructively the bench consists of a body, where electrical equipment, electronic boards, frontal panel and tabletop are installed.

The body contains:

- power source with short circuit and neutral protection ;

- measurement system;

- voltage controllers (smooth adjustment, overload and short circuit protection);

- storage of hot and cold water with automatic stabilization of specified temperature (2 pcs.);

- circulation pumps;

- vacuum pump;

- air temperature sensor;

- atmospheric pressure sensor;

- electromagnetic valves for changing the direction of fluid flow.

On the frontal panel the following items are located:

- bench power source controllers;

- actuating mechanisms controllers;

- sockets for connecting interchangeable modules measurement circuits;

- socket for connecting interchangeable modules power circuits;

- sockets for connecting interchangeable modules measurement and power circuits;

- USB port for connecting measurement system to PC;

- wiring field for investigated devices (780×600 mm).

Wiring field allows hot change of the modules investigated without special tools and it’s firm enough to fix them. The following elements are located there:

- hot water flow controller;

- cold water flow controller;

- pressure controller;

- circulation pumps outputs;

- vacuum pump output;

- compressor output.

The outputs of circulation pumps, vacuum pump, compressor are quick disconnectable.

Measurement system includes the following sensors:

- temperature sensors (11 pcs.);

- pressure sensors (including differential, 4 pcs.);

- heat transfer rate meter (1 pc.);

- fluid flow meter (2 pcs.);

- air flow meter (1 pc.);

- electric power meter (1 pc.).

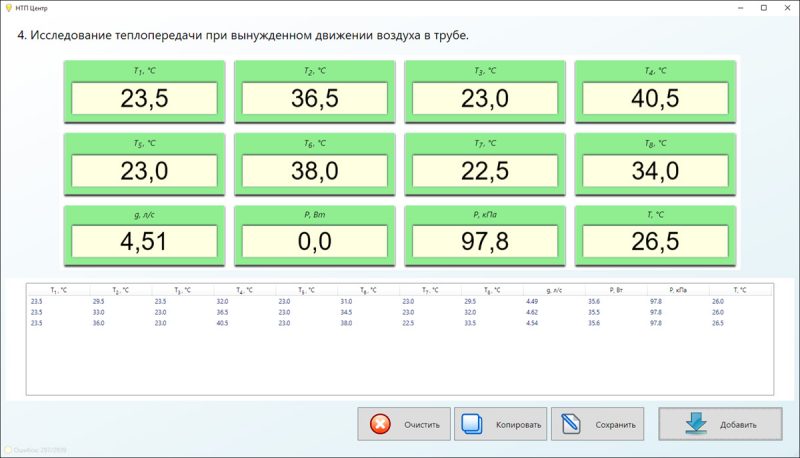

Measurement system characteristics:

- temperature measurement accuracy – 0.5 ◦С;

- electric power measurement accuracy – 0,5W;

- other measurements accuracy – 2%;

Measurement system provides hot and cold water temperature stabilization in storage tank. There’s a possibility of PC connection via USB port to transfer all the information.

The training system is accompanied with:

- software;

- a set of teaching materials and technical documentation intended for the teaching staff.

Experiments provided

- Investigation of thermal conductivity of materials using the plate method (module NTC-22.05.1/1).

- Investigation of heat transfer by natural convection of the air near the horizontal cylinder (module NTC-22.05.1/2).

- Investigation of heat transfer by natural convection of the air near the vertical cylinder (module NTC-22.05.1/2).

- Investigation of heat transfer by forced air movement in pipe (module NTC-22.05.1/4).

- Investigation of adiabatic gas outflow through narrowing nozzle (module NTC-22.05.1/5).

- Determination of emissivity coefficient of eletcroconductive materials using the calorimetric method (module NTC-22.05.1/6).

- Investigation of heat process in tube-in-tube heat exchanger (module NTC-22.05.1/7).

Additional modules (not included in the bench set):

- Determination of viscosity aircoefficient (module NTC-22.05.1/8).

- Determination of thermal capacities with a fixed pressure and fixed amount attitudes (module NTC-22.05.1/9).

- Studying of the technical heat exchanger (module NTC-22.05.2/2).

Technical specifications

| Power supply | ~220 50Hz | |

| Power consumption, kW, max | 2 | |

| Bench overall dimensions, max | ||

| width, mm | 1310 | |

| height, mm | 1450 | |

| depth, mm | 600 | |

| Weight, kg, max | 210 | |

Video

Scope of delivery

- laboratory bench – 1 pc.;

- set of interchangeable modules – 1 pc.;

- USB 2,0 AM-BM cable – 1 pc.;

- passport – 1 pc.;

- supplementary materials in electronic format – 1 pc.

Русский

Русский