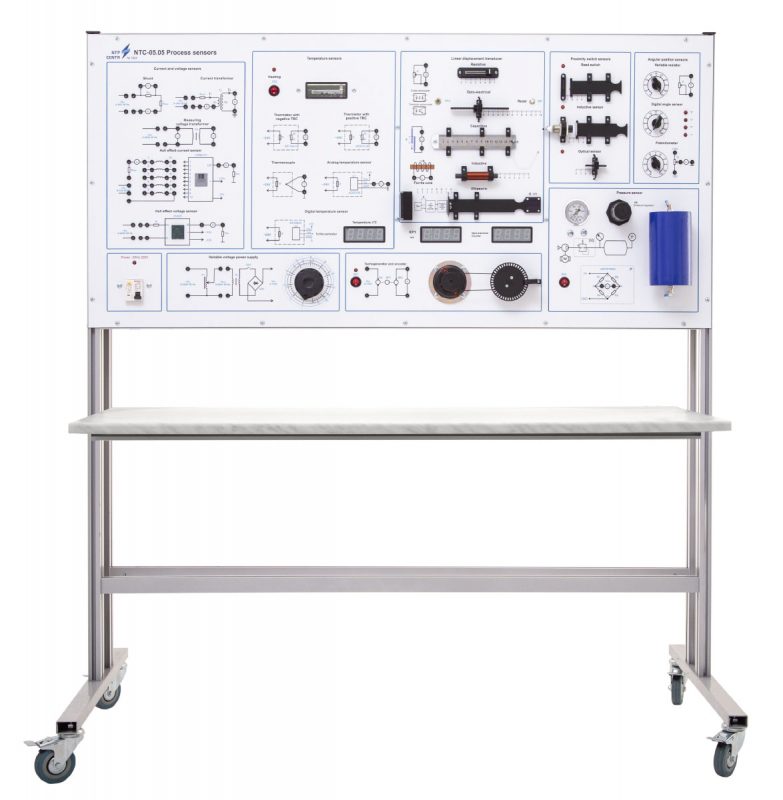

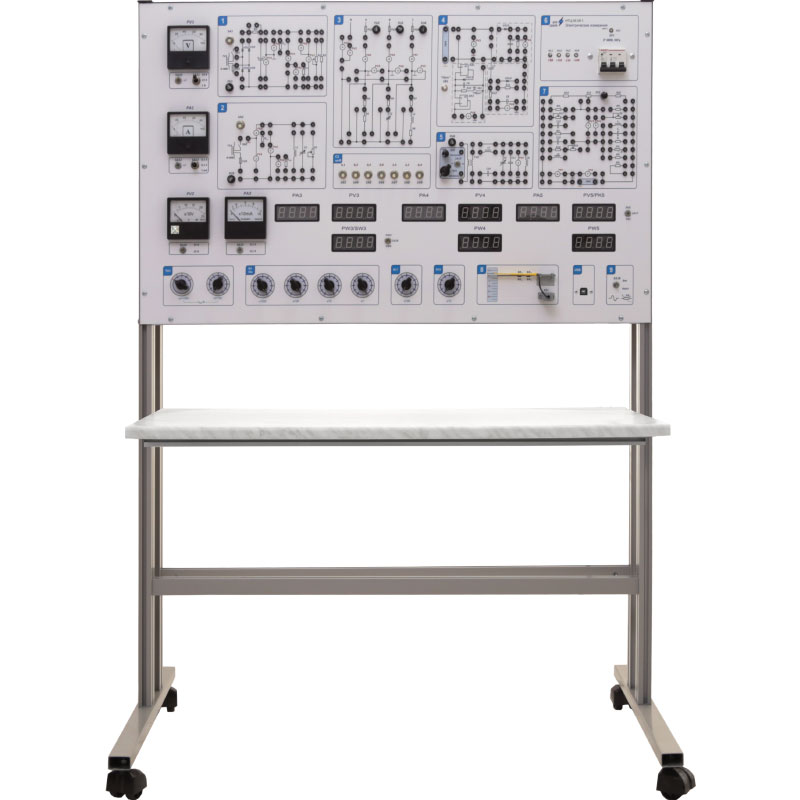

Measurements and metrology

The training laboratory is designed for institutions of higher, secondary specialized and vocational education.

A number of training stands which are an integral part of laboratory make it possible to get practical skills about measuring instruments operation of various systems and calibration these instruments.

Русский

Русский