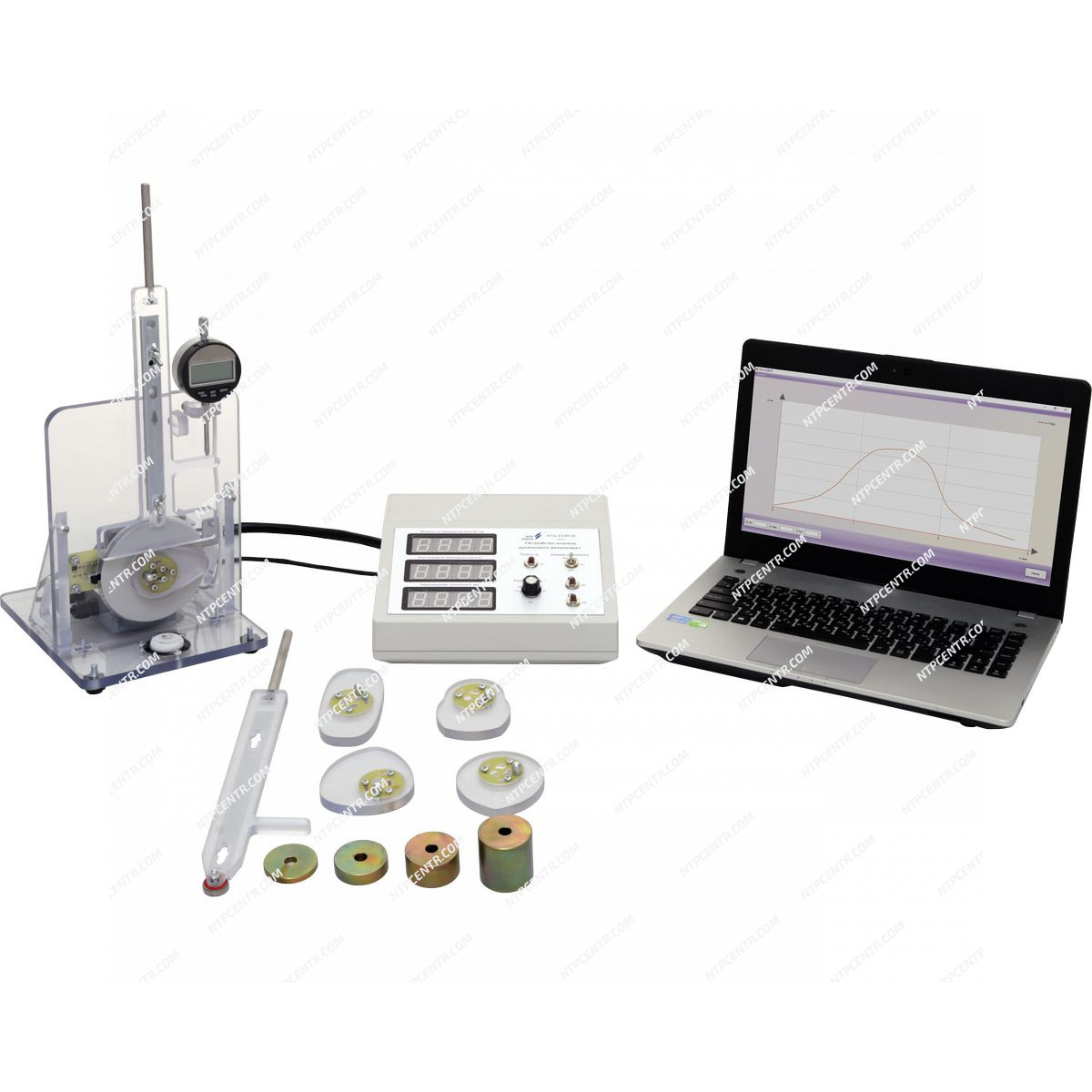

NTC-13.09.19 “Analysis device of camshaft mechanism”

Br0.00

The educational laboratory stand is designed for use as training equipment in higher education institutions, secondary specialized schools, and vocational-technical colleges during laboratory and practical lessons on kinematic analysis of cam mechanisms and determining the pressure angle to evaluate their operation and characteristics.

*For more information, you can contact us using the phone numbers or email provided on the website.

Русский

Русский