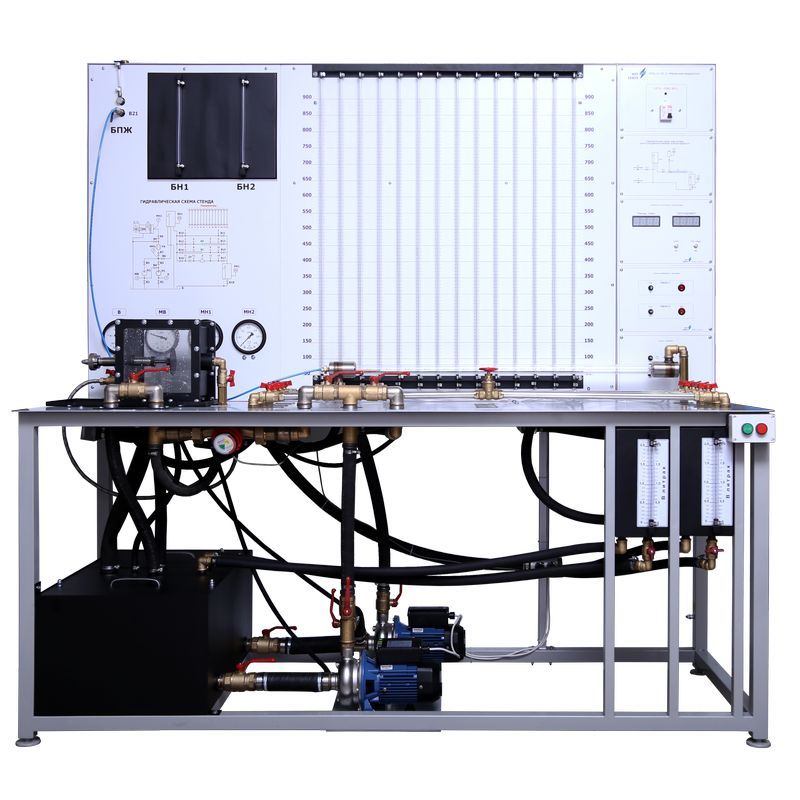

NTC-11.91.2 “Fluid mechanics”

Br0.00

The educational laboratory stand is designed for conducting laboratory work in the course “Hydraulics” at higher education institutions, colleges, and vocational-technical schools. These activities cover methods for measuring and analyzing hydraulic characteristics of systems, including determining water flow rates by various methods, studying flow regimes and pressure losses in pipelines, and when passing through different resistances. Additionally, the effects of fluid jet forces on obstacles are examined, fundamental hydrodynamic equations such as Bernoulli’s equation are demonstrated, and the characteristics of pumps are studied under different connection schemes to assess their efficiency and performance.

*For additional information, please contact us via the phone numbers or email provided on the website.

Русский

Русский