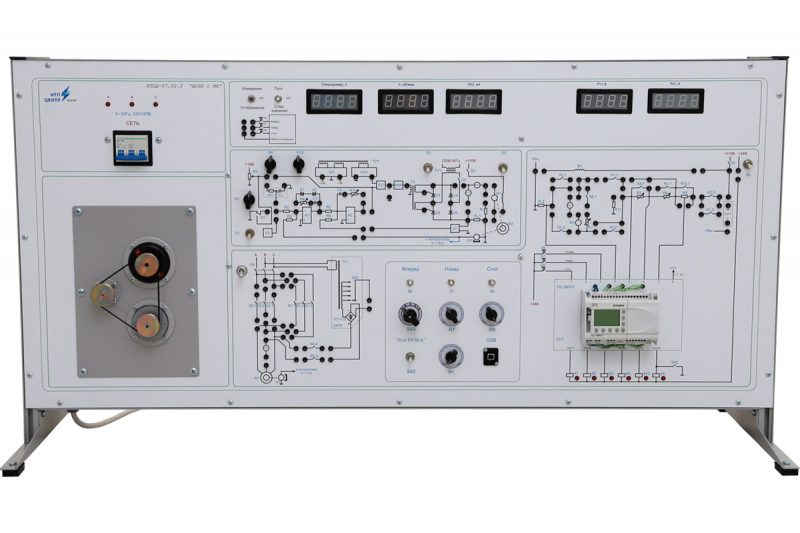

NTC-07.02.2 “Electric drive automatic control with MC”

Br0.00

The educational laboratory stand is designed for studying automated electric drives with control systems based on PLCs, investigating startup, braking, and control processes of electric machines, as well as the operation of converters. The research includes analyzing the dynamics of start-up and braking for direct current and asynchronous motors, as well as studying automatic control systems—both open-loop and closed-loop.

*For additional information, you can contact us via the phone numbers or email provided on the website.

Русский

Русский