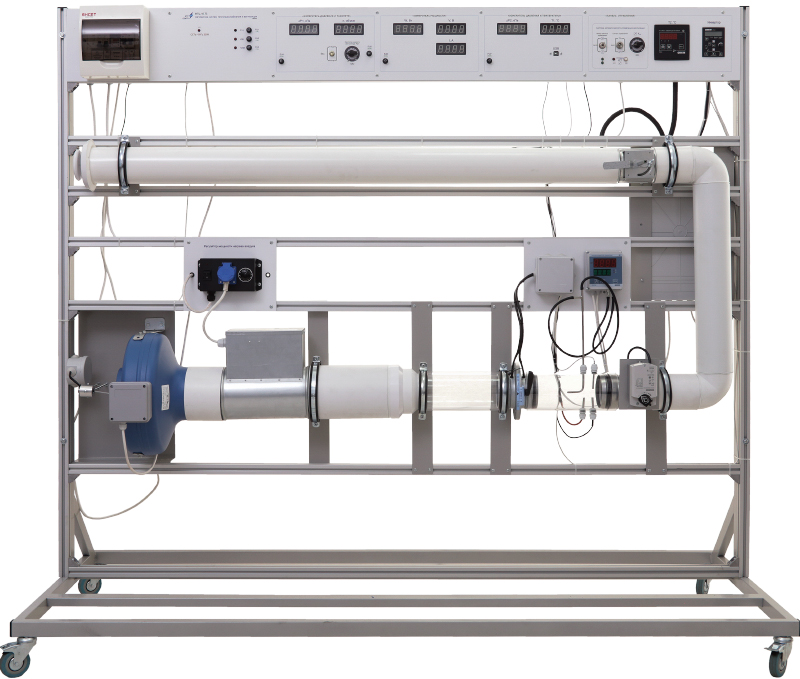

NTC-16.73 “Automatics of heat and gas supply and ventilation systems”

Br0.00

The laboratory stand is intended as the training equipment at secondary specialized colleges and higher educational establishments for laboratory classes to study automatics of heat and gas supply and ventilation elements, methods to regulate and monitor temperatures, pressure and gas flow.

Русский

Русский