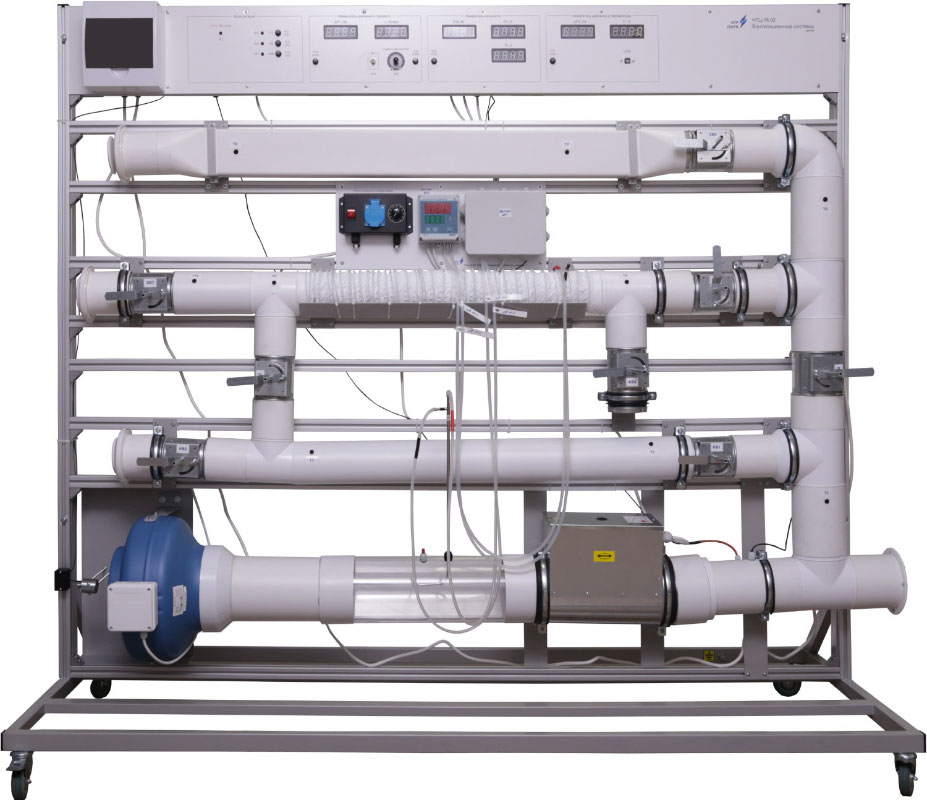

NTC-16.02 “Ventilation systems”

Br0.00

The training laboratory stand is intended to study ventilation system elements, methods to regulate and monitor parameters in ventilation systems with various air duct configurations, to determine hydraulic resistance of ventilation system elements, to study air heating control systems.

The movable platform accommodates main equipment:

- centrifugal fan;

- tachogenerator;

- chanel electrical heater;

- system of valves and air ducts of various shapes and materials;

- microprocessor- based measuring system.

Air ducts are designed as circular 100 mm diameter and rectangular cross-section pipes made of PVC, circular transported 100 mm diameter pipe, flexible 100 mm diameter hose made of PVC. The ducts are mounted on the front side of the mounting frame.

The measuring system allows to register static and dynamic pressure in metering sections, rotation speed of the fan impellers, voltage, current, active power of the fan electric motor, air temperature in the duct. Differential pressure transducers are used to measure static and dynamic pressure. Pressure sensors are connected to air ducts via a system of tubes.

Microprocessor-based control and measuring system has a modular design combining autonomous units. Microprocessor-based system includes the following units:

- inlet unit;

- power supply unit;

- pressure measuring and tachogenerator unit;

- power measuring unit;

- pressure and temperature measuring unit.

The stand is accompanied with a set of teaching materials and technical documentation intended for the teaching staff.

Experiments provided

- Studying pressure measuring instruments and methods.

- Studying velocity distribution profiles (by the value of dynamic pressure) for the air flowing through a circular duct using Pitot tube. Determining flows by the velocity profile

- Studying characteristics of a fan.

- Studying characteristics of various types of ducts: determining losses of pressure head along the length, resistance and friction coefficients.

- Studying losses of pressure head on a local resistance – a regulated flap. Determining the resistance coefficient of the flap, the discharge coefficient.

- Studying characteristics of the duct system when the ducts are connected in sequence.

- Studying characteristics of the duct system when the ducts are connected in parallel.

- Determining power of the heater to achieve the required air temperatures.

- Studying air heating control systems: stepless and stepped.

3D model

Technical specifications

| Power supply | ~220 V, 50Hz (one phase 220 V, 50 Hz) |

| Consumed power, kW, not more than | 2,3 |

| Overall dimensions of the control unit, not more than: | |

| Width, mm | 2020 |

| Height, mm | 1820 |

| Depth, mm | 770 |

| Weight of the equipment, kg, not more than | 70 |

Scope of delivery

- training laboratory stand – 1 pc.;

- passport – 1 pc.;

- supplementary materials in electronic format – 1 pc.

Русский

Русский