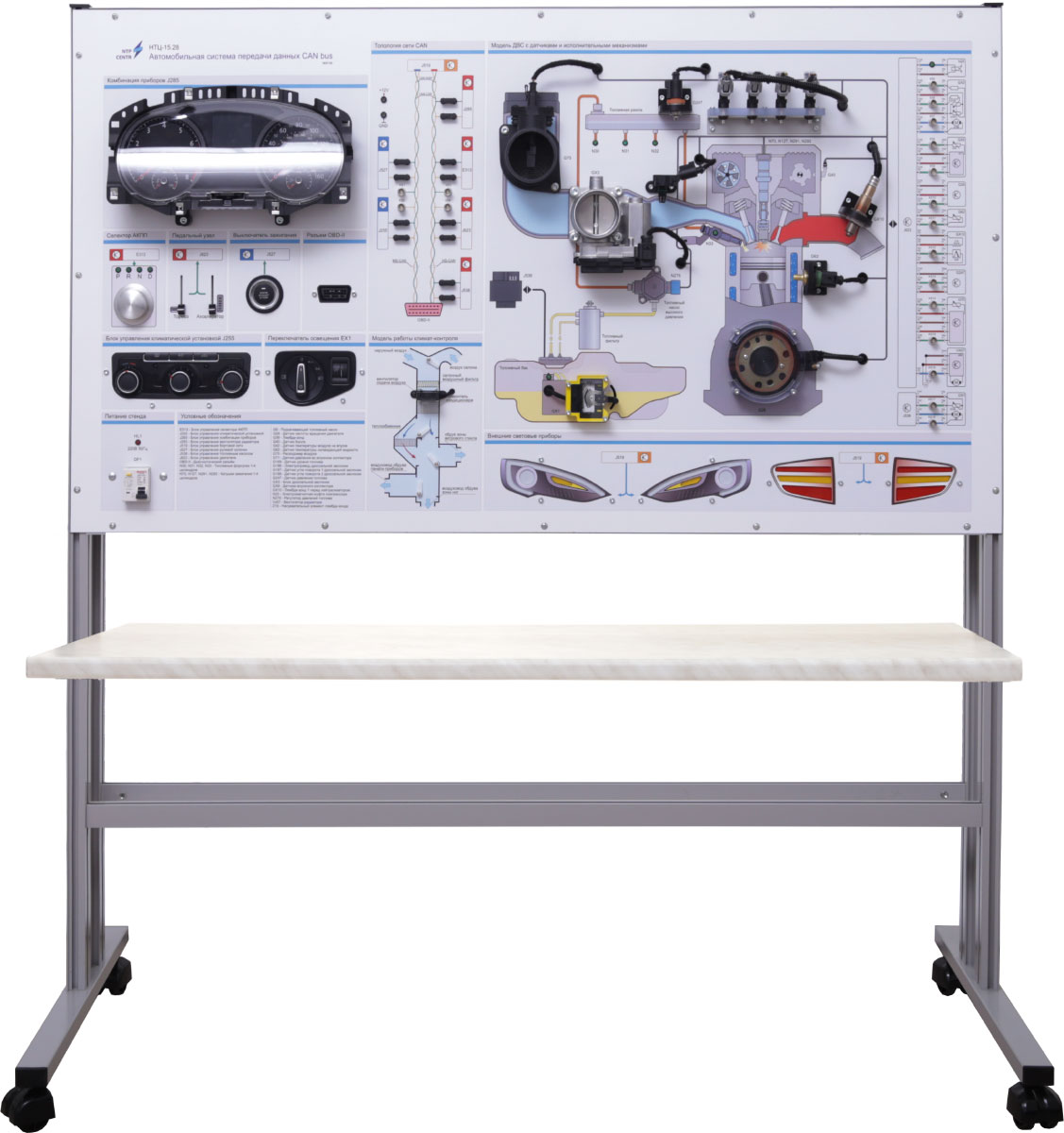

NTC-15.28 “Automotive CAN Bus Data Transmission System”

Br0.00

The training laboratory stand is designed for conducting experiments to study the serial CAN bus system that is used in modern automotive electronic systems. This set of laboratory work covers the fundamental aspects of automotive communication systems. Students will learn the principles of how the CAN bus and its physical layer operate, practice listening to and decoding CAN traffic, and analyze the structure of messages and how to work with them. Additionally, the coursework includes handling errors and methods for network recovery, as well as studying the UDS protocol used for vehicle diagnostics and maintenance. These hands-on exercises provide a comprehensive understanding of modern automotive information and diagnostic systems.

*For additional information, you can contact us using the phone numbers or email provided on the website.

Русский

Русский