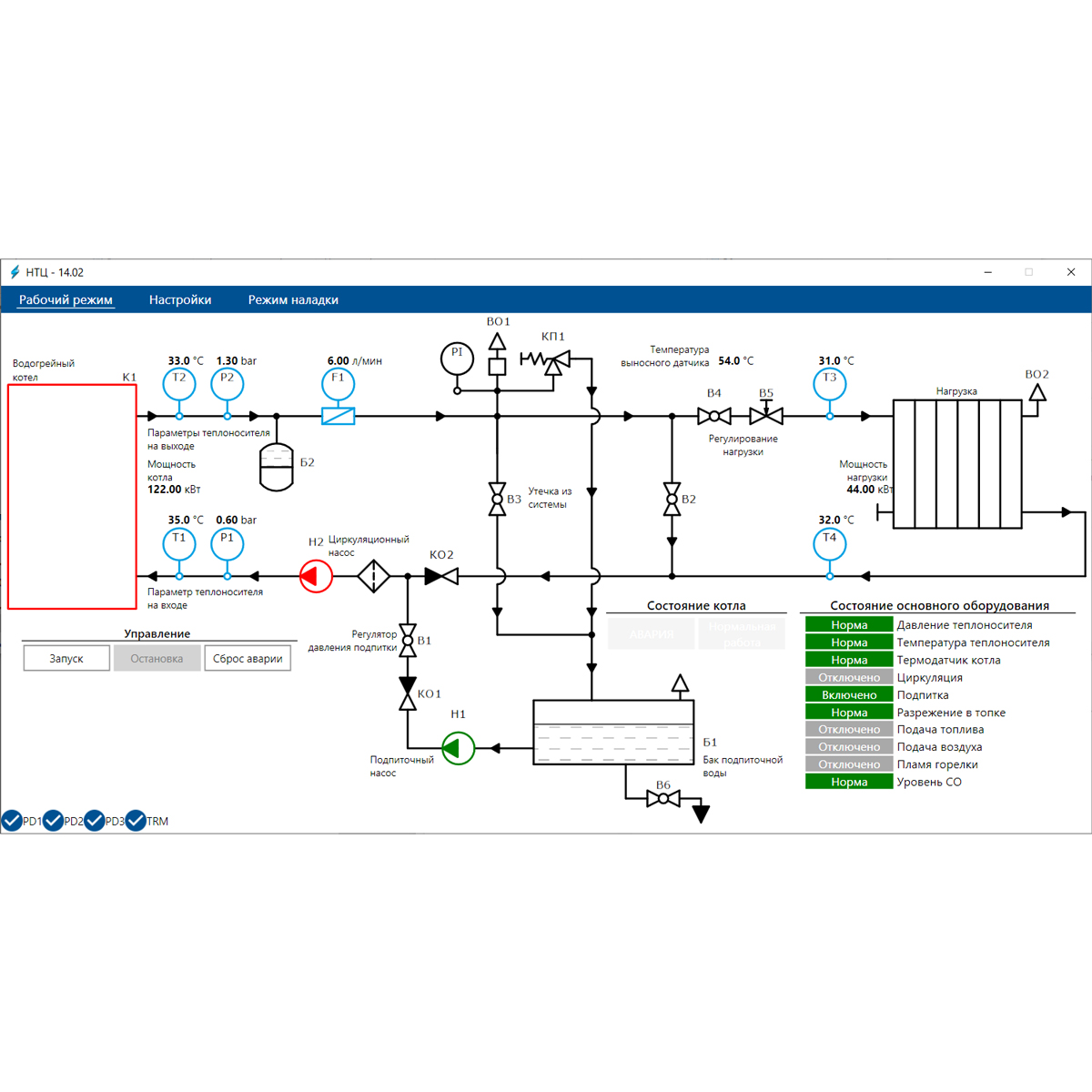

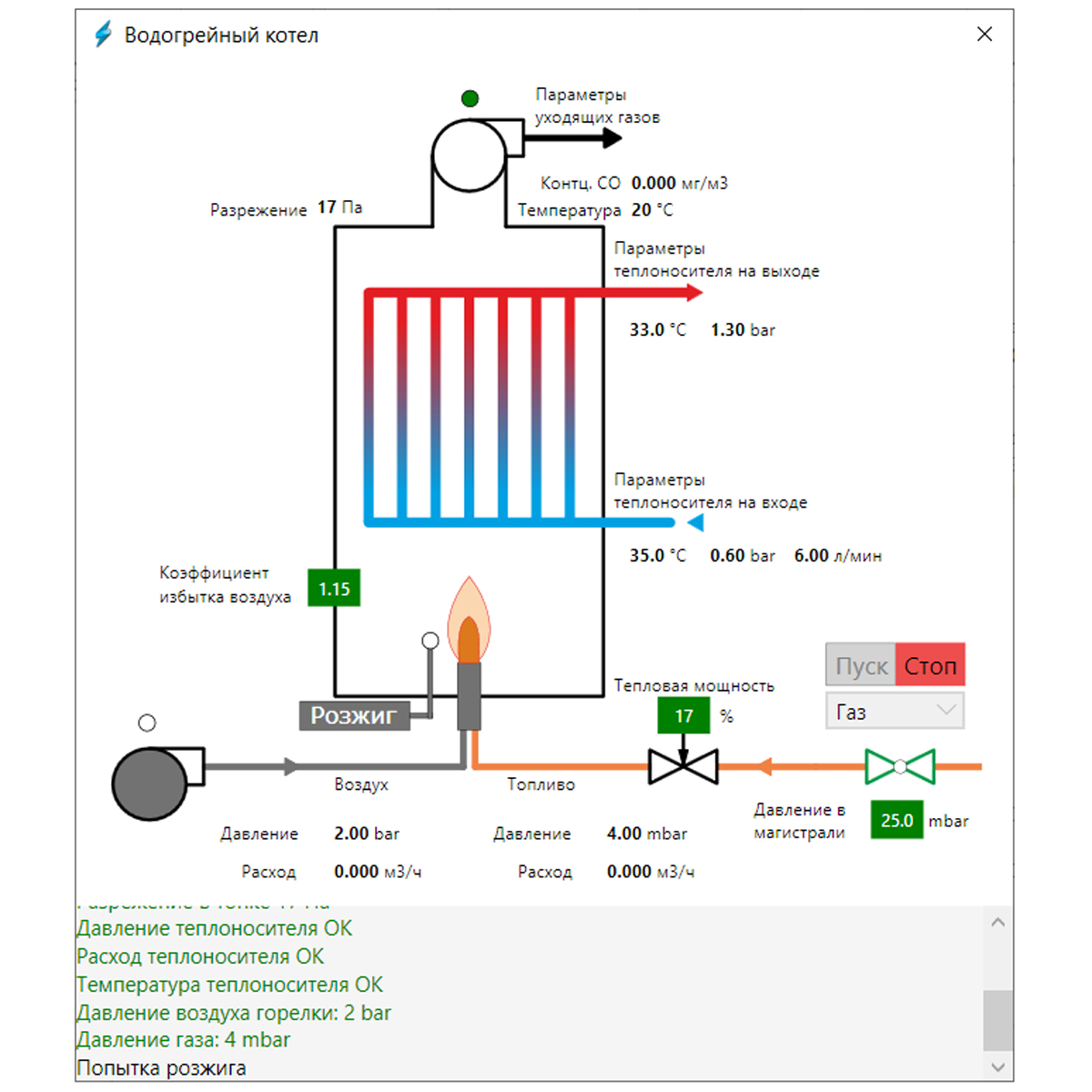

NTC-14.02 “Automated liquid and gaseous boiler station”

Br0.00

The training laboratory system is designed to be used as the educational equipment during the classes on the study of working principle of liquid and gaseous boiler station, processes, arising during the work of boiler station, for determination of energy and boiler’s efficiency, heating loads of the consumer.

Русский

Русский