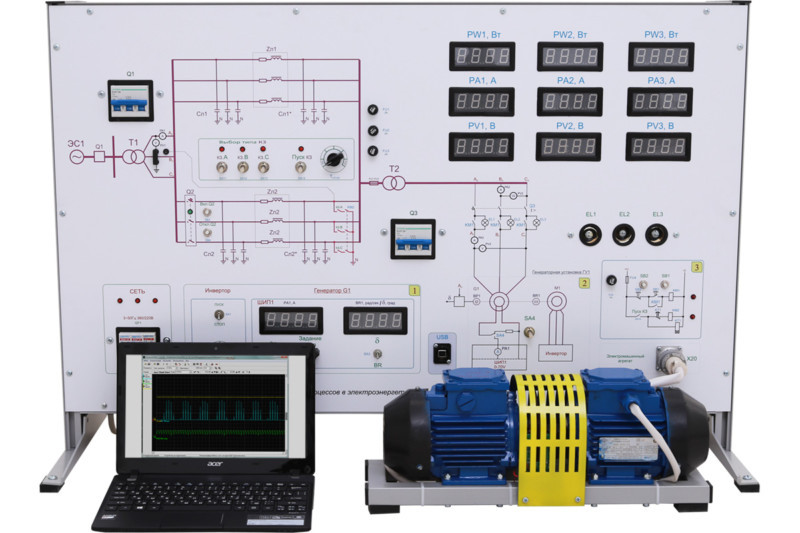

NTC-10.72 “Simulation of transitory processes in electricity power supply systems”

Br0.00

The educational laboratory stand is designed for use as training equipment in higher education institutions, secondary specialized schools, and vocational-technical colleges during laboratory and practical lessons on studying the operating modes and static stability of a basic electrical system using an electrodynamic model. Additionally, it facilitates analysis of the impact of various types of short circuits on the dynamic stability of the power transmission system. The asynchronous mode of system operation is examined, and characteristics of the mode of a simple system consisting of two stations of equal capacity are recorded.

*For more information, you can contact us using the phone numbers or email provided on the website.

Русский

Русский