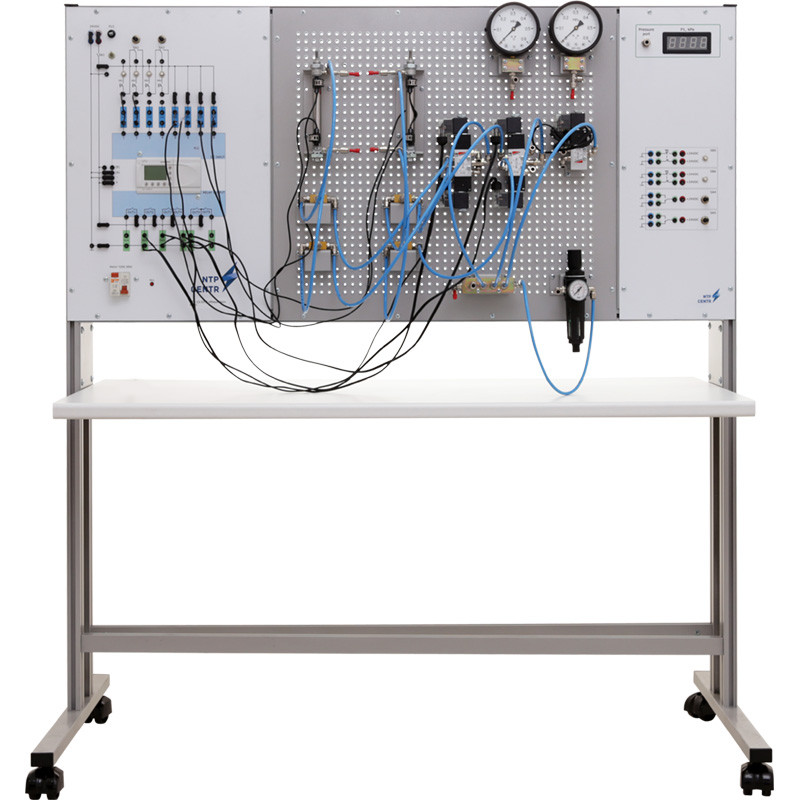

NTC-12.03.B “Pneumatics”

Br0.00

The stand is used for conducting laboratory work aimed at training specialists in the field of automation of production processes, designing automatic control systems, and servicing pneumatic automation systems. The basic component base and operational characteristics of equipment are studied, and pneumatic and electro-pneumatic control systems are researched and developed, including the determination of component characteristics, testing of pneumatic valves and cylinders, as well as the creation and programming of automated control systems using PLCs and software to implement cyclic motions and logical operations.

*For more information, you can contact us using the phone numbers or email provided on the website.

Русский

Русский