NTC-22.05.15 “Study of thermal characteristics of metals”

Br0.00

- Description

- Technical specifications

- Video

- Scope of delivery

- Additional equipment (specified when ordering)

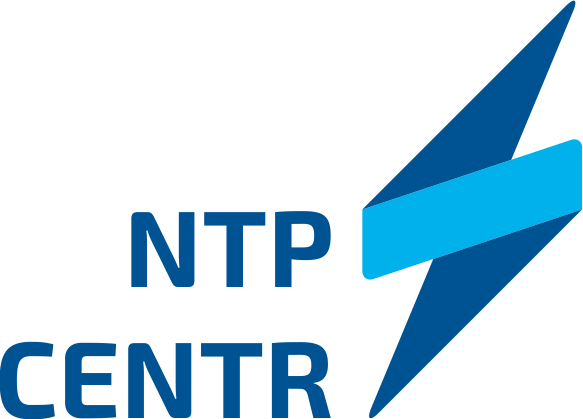

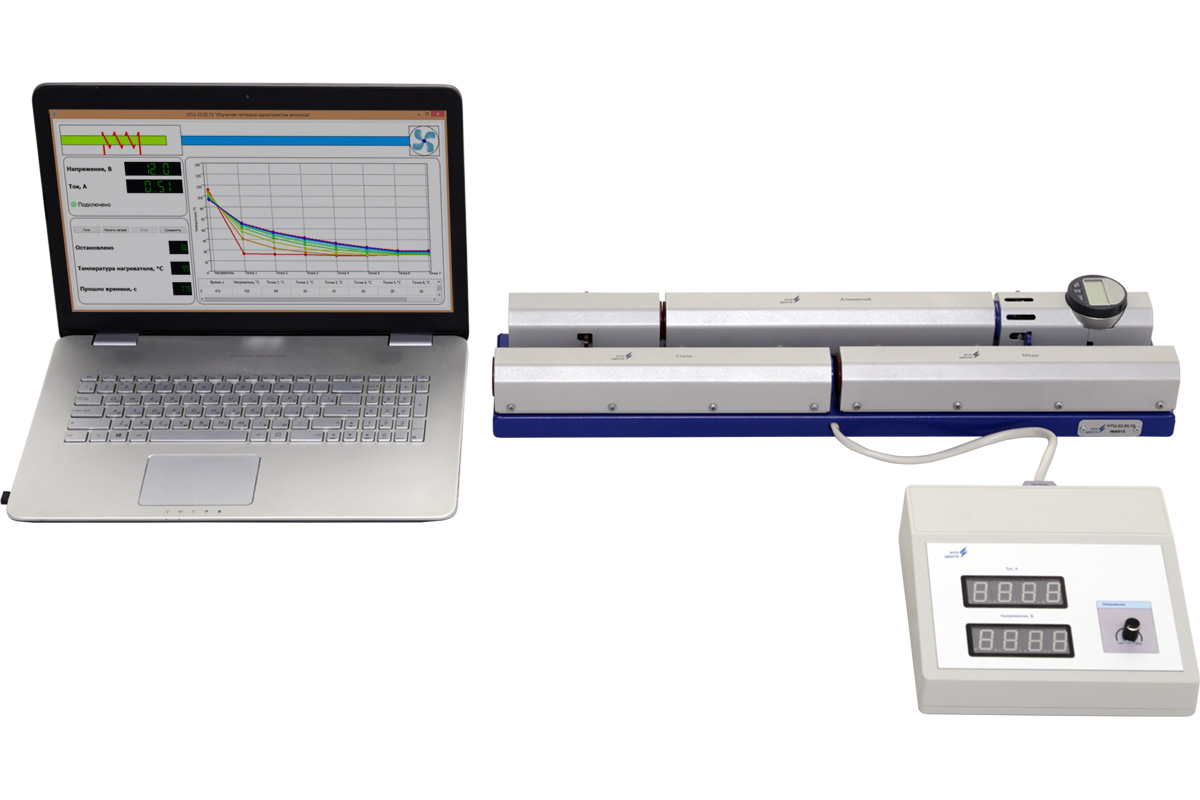

The heating unit consists of a heating module, cooler, electromagnetic and mechanical clamps, three insulated patterns with mounted thermocouples, and metal foundation.

The control unit sets the heating power, cooling capacity, switches on the electromagnetic clamp, reads data from the temperature sensors, and transmits the measurement results via USB-port to the PC (in not included in delivery set).

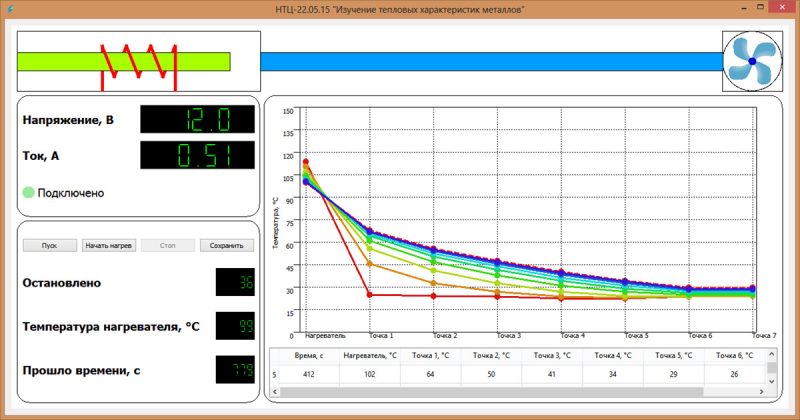

To perform the experiment, the pattern is placed between two metal functional modules of the unit: the heating module and the cooling module. The required heating power is set by the control unit regulator. After the heater temperature reaches a steady state value, the button “start” turns on the electromagnetic clamp, and the pattern’s heating starts from one side simultaneously with its cooling from the other side. Along the entire pattern length at regular intervals temperature sensors are installed. The information from them is transmitted to the PC. In a metal cylindrical rod, at the ends of which different temperatures are maintained, a temperature drop along its length is set after some time. Temperature decreases uniformly from the warm end to the cold one, and a constant flow of heat emerges in the rod. The software detects the temperature distribution along the rod at equal time intervals. Thermal conductivity is calculated when processing of the obtained measurement results.

The experiment for determining the dependence of the linear expansion of solids is similar to the previous one, but the cooler is not used in it. After the heating of the metal sample begins on the one side, the micrometer on the other side records the change in the length of the sample. This information is also transmitted by the control unit to the computer. At processing the obtained measurement results is calculated the value of linear expansion of the sample from temperature.

The laboratory unit has a computer-animated model of the experiment, which is designed for the visualization of conductive heat transfer processes in metals that occur during the transition from the heated zone to the cold one.

The training system is accompanied with:

- a set of teaching materials and technical documentation intended for the teaching staff;

- a software.

Technical specifications

| Voltage | ~50Hz 220V (single-phase 220V 50Hz) | |

| Power consumption, kW, max | 0,06 | |

| Control unit dimensions, max | ||

| width, mm | 230 | |

| height, mm | 80 | |

| depth, mm | 220 | |

| Heating unit dimensions, max | ||

| width, mm | 645 | |

| height, mm | 100 | |

| depth, mm | 135 | |

| Weight, kg, max | 9,5 | |

Video

Scope of delivery

- training laboratory system – 1 pc.;

- passport – 1 pc.;

- supplementary materials in electronic format – 1 pc.

Русский

Русский