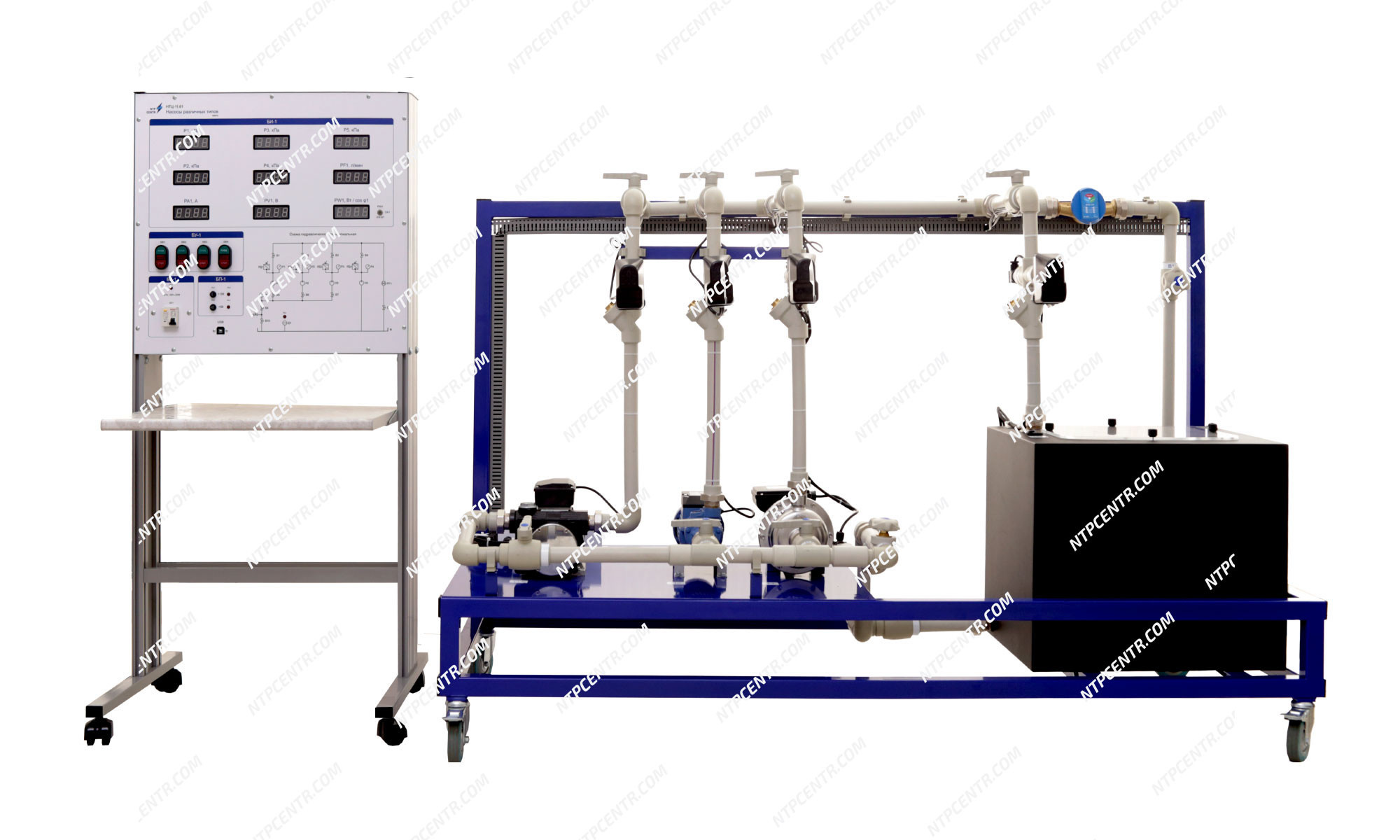

NTC-11.61 “Different types of pumps”

Br0.00

The training laboratory equipment is dedicated for performing the laboratory works dedicated for studying the operation of water pump with different types arrangement.

*For additional information, please contact us via the phone numbers or email provided on the website.

Русский

Русский