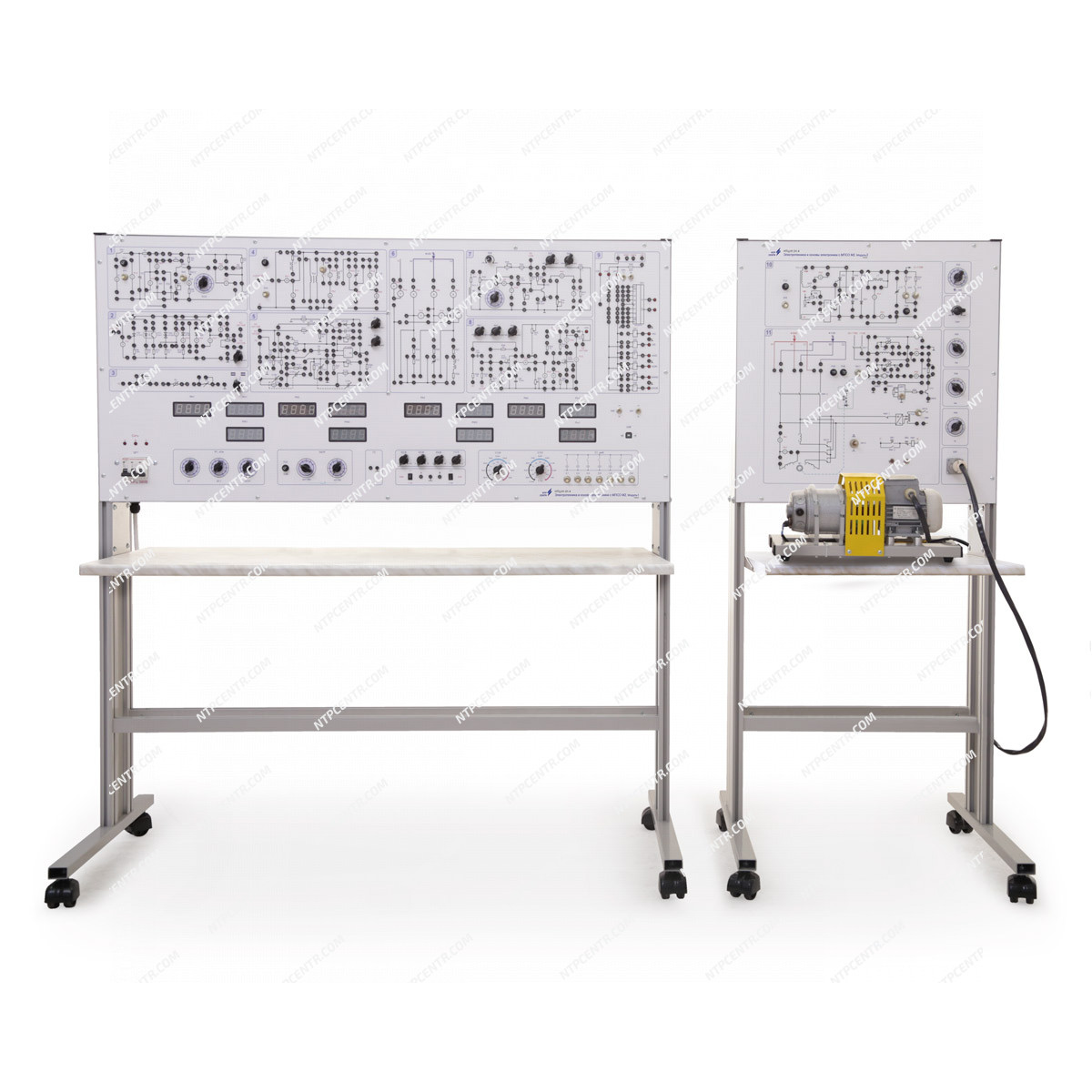

NTC-01.01.4 “Electrical engineering and basic electronics M2”

Br0.00

The educational laboratory stand is designed for use as training equipment in higher, secondary specialized, and vocational-technical educational institutions for conducting laboratory and practical classes in electrical engineering and fundamentals of electronics. During these sessions, methods and tools for measuring electrical quantities are studied, as well as the characteristics of various electrical circuits and devices. Both theoretical foundations and experimental methods for determining element and circuit parameters are examined, including the use of measuring bridges, connection schemes for components, and studies of nonlinear and linear circuits of direct and alternating current. Particular attention is given to the characteristics of semiconductor devices (diodes, transistors, thyristors), the operation of amplifiers, filters, voltage stabilizers, as well as the analysis of three-phase systems and electric motors. An essential part involves studying digital elements and control system circuits.

*For additional information, you can contact us via the phone numbers or email provided on the website.

Русский

Русский