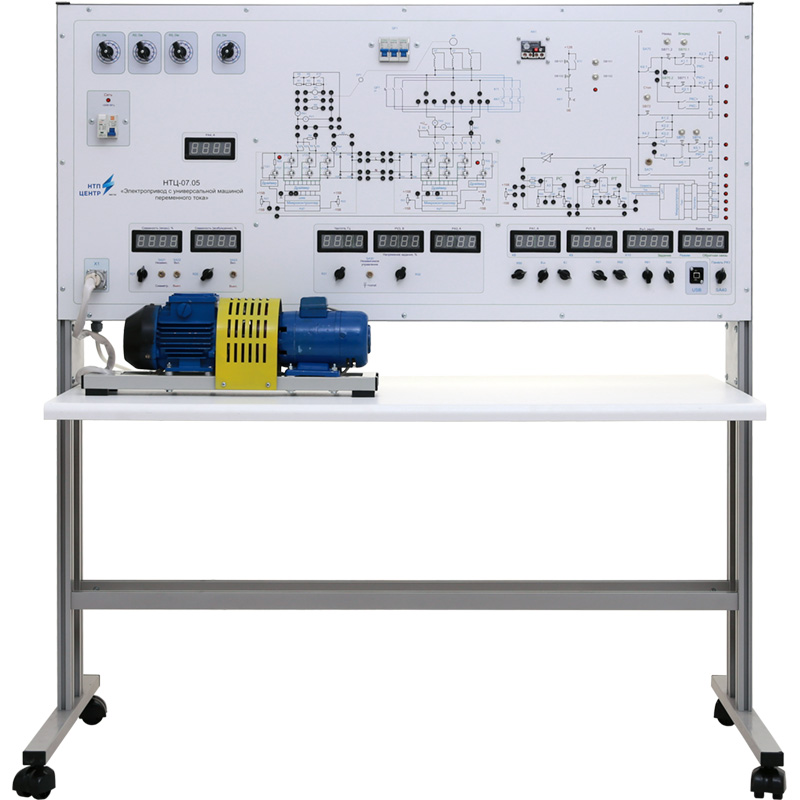

NTC-07.05 “Fundamentals of electric drive and converting technologies with MPCS”

Br0.00

The educational laboratory stand is designed for studying automated electric drives, power conversion techniques, drive control systems, and automatic control systems. Laboratory work includes examining the static and dynamic characteristics of direct current and asynchronous motors, as well as their operating modes in braking and starting conditions. Static characteristics are measured in various quadrants, and braking methods such as dynamic braking, counter-current braking, as well as resistor starting and the influence of parameters on startup processes are studied. Additionally, the principles and circuits of converters (including broad-bandwidth pulse-width modulation converters based on IGBT transistors and autonomous inverters) are explored, along with the experimental determination of machine parameters such as inertia moment. Automatic regulation systems are analyzed, including current, speed, and positional control with regulator design and static characteristic analysis at different feedback coefficients. Protection systems for electric motors are also examined, including thermal protection based on thermal relays and overcurrent protection with automatic circuit breakers.

*For additional information, you can contact us via the phone numbers or email provided on the website.

Русский

Русский