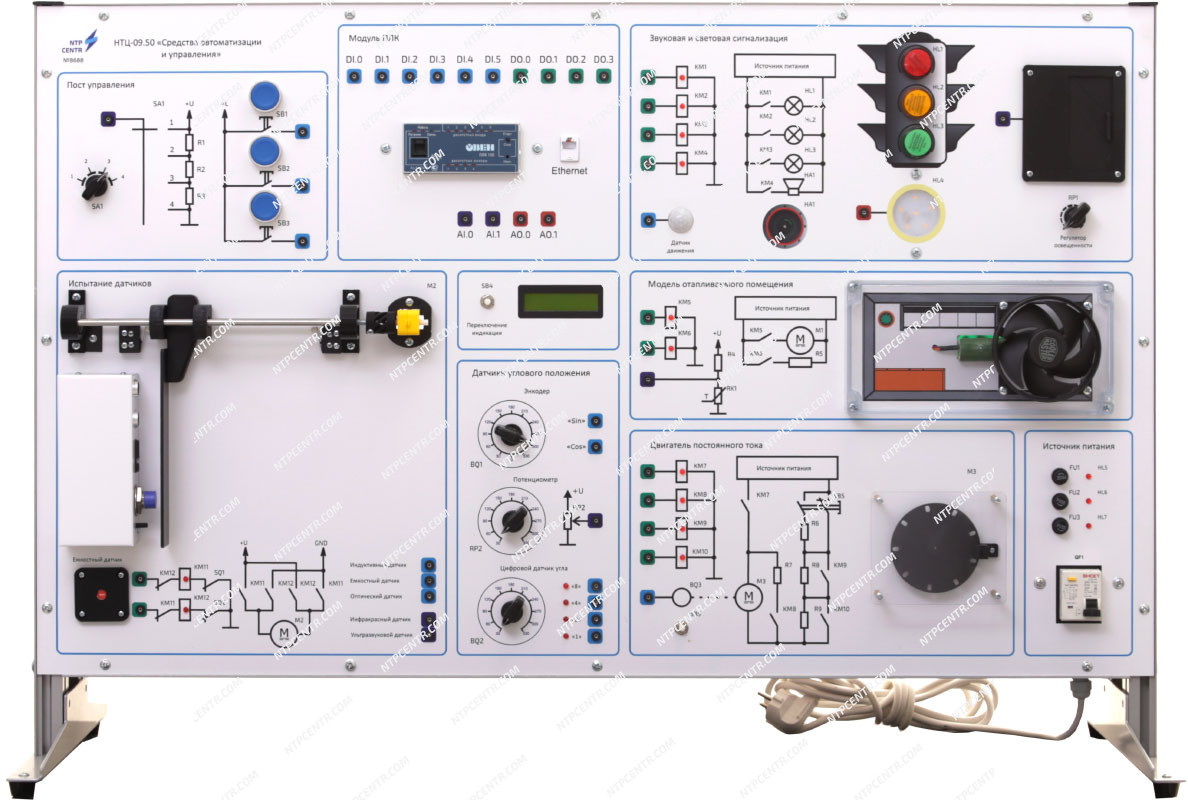

NTC-09.50 “Automation and control means”

Br0.00

The educational laboratory stand is designed to acquire basic and advanced professional knowledge and skills in developing various automatic control systems based on programmable logic controllers, testing their logical functions, and systems for automatic control of different objects and processes. This includes systems for lighting, signaling, temperature regulation, and motor control using sensors.

*For more information, you can contact us using the phone numbers or email provided on the website.

Русский

Русский